Pioneering Solutions for

Critical Care and

Antimicrobial Therapy

Dry Injections from Maya Biotech

Uncompromising Quality and Regulatory Compliance

Our dry injection manufacturing processes adhere to the most stringent international standards, including cGMP, ISO, and ICH guidelines. We subject each batch to rigorous testing and quality control measures to ensure:

Moisture content and lyophilization cycle optimization

API potency and purity

Sterility and endotoxin control

Particulate matter and foreign particle elimination

Moisture content and lyophilization cycle optimization

API potency and purity

Sterility and endotoxin control

Particulate matter and foreign particle elimination

Our Dry Injections

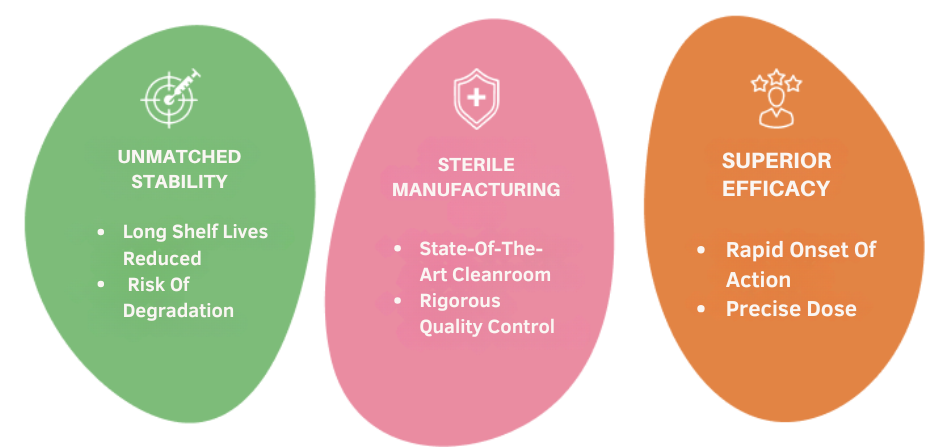

Engineered for Stability, Precision, and Rapid Efficacy

UNMATCHED STABILITY

- Extended Shelf Life for Reliable Storage

- Minimized Risk of Product Degradation

STERILE MANUFACTURING

- State-of-the-Art Cleanroom Production

- Rigorous Quality Control for Consistent Safety

SUPERIOR EFFICACY

- Fast-Acting Formulations for Immediate Therapeutic Effect

- Precise Dosing for Targeted Treatment

A Comprehensive Range of Dry Injection Solutions

We offer an advanced portfolio of dry injection formulations, delivering long-lasting stability, stringent sterility, and rapid therapeutic action across a variety of critical care.

Critical Care General Dry Injection

Our critical care dry injection portfolio encompasses a wide array of essential medications, including

- Potent antibiotics like Methylprednisolone Sodium Succinate, Vancomycin, and Tigecycline

- Vital immunomodulators such as Hydrocortisone and Methylprednisolone

- Targeted therapies for specific conditions, including Voriconazole for fungal infections and Rabeprazole for acid-related disorders

Cephalosporin Dry Injection

We offer an extensive range of Cephalosporins, the workhorses of antimicrobial therapy:

- Broad-spectrum antibiotics like Cefepime, Ceftriaxone, and Meropenem

- Potent combination therapies, including Cefoperazone-Sulbactam and Imipenem-Cilastatin

- Advanced formulations engineered for enhanced stability and efficacy

Critical Care General Dry Injection

Our critical care dry injection portfolio encompasses a wide array of essential medications, including

- Potent antibiotics like Methylprednisolone Sodium Succinate, Vancomycin, and Tigecycline

- Vital immunomodulators such as Hydrocortisone and Methylprednisolone

- Targeted therapies for specific conditions, including Voriconazole for fungal infections and Rabeprazole for acid-related disorders

Cephalosporin Dry Injection

We offer an extensive range of Cephalosporins, the workhorses of antimicrobial therapy:

- Broad-spectrum antibiotics like Cefepime, Ceftriaxone, and Meropenem

- Potent combination therapies, including Cefoperazone-Sulbactam and Imipenem-Cilastatin

- Advanced formulations engineered for enhanced stability and efficacy

Pioneering Formulation Methodologies

Our dry injection formulations are developed using advanced technologies that prioritize both stability and efficacy. This includes:

Dosing

Power

Disperson

and uniform distribution

in the aerosol.

Pioneering Formulation Methodologies

Our dry injection formulations are developed using advanced technologies that prioritize both stability and efficacy. This includes:

Lyophilization

Ensures optimal drug dispersion and deep lung penetration.

Precision Dosing

Improves drug stability and uniform distribution in the aerosol.

Advanced Power Disperson

Deliver a smooth, comfortable actuation experience for patients.

How Brands Have Leveraged Our Capabilities

Challenge:

A client needed a reliable manufacturing partner to fast-track the production of Anidulafungin Injection for the treatment of fungal infections, with strict quality and regulatory requirements.

Solution:

We developed Anidulafungin Injection with optimized lyophilization cycles, precise moisture control, and global regulatory compliance, ensuring product stability and high efficacy.

Result:

The product was successfully launched within the committed timeline, helping the client quickly address critical care needs and establish a trusted presence in the antifungal therapy market.

Challenge:

A partner brand urgently required large-scale production of Meropenem Injection to meet rising demand for broad-spectrum antibiotic treatments in critical care settings.

Solution:

We efficiently manufactured Meropenem Lyophilized Injection, ensuring sterile processing and strict compliance with global antibiotic manufacturing standards.

Result:

The product was delivered ahead of schedule, enabling the client to quickly penetrate the hospital supply chain.

Case Study - 1

Rapid Anti-Fungal Solution

Case Study - 2

Streamlined Antibiotic Production

Solution: We efficiently manufactured Meropenem Lyophilized Injection, ensuring sterile processing and strict compliance with global antibiotic manufacturing standards.

Result: The product was delivered ahead of schedule, enabling the client to quickly penetrate the hospital supply chain.

Our Complete Dry Injections Portfolio

Explore our extensive range of meticulously crafted dry injection formulations. Click on each product to view detailed information, including composition, indications, and unique benefits.

Consistent Quality and Regulatory Compliance

With over a decade of expertise in inhaler formulations, our team of experts ensures each product adheres to the strictest regulatory standards, including Global FDA, EMA, and local guidelines.

We follow comprehensive testing protocols to ensure consistent quality, efficacy, and safety in every batch.